Roper Pumps

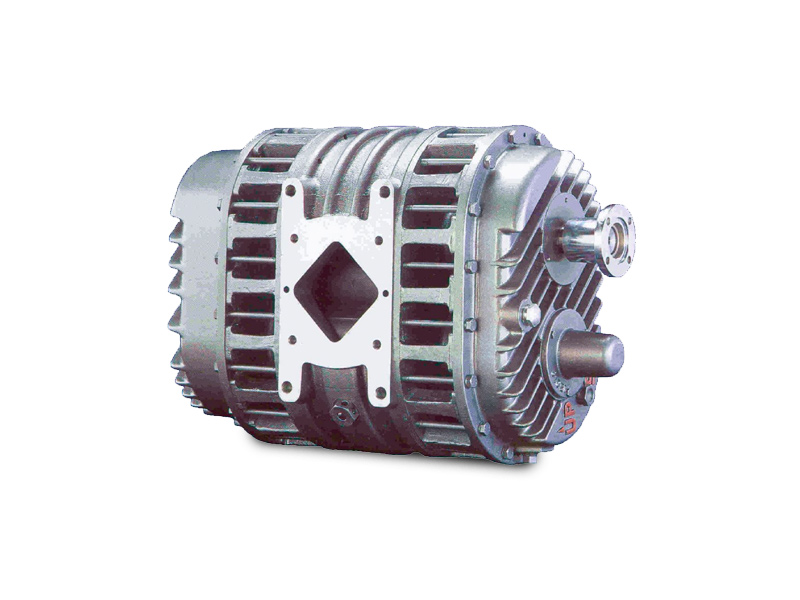

The Roper Pumps 3600 series, in particular, comprises general-purpose pumps capable of handling mixing, blending, recirculating, fixed, and mobile transfer tasks, with capacities of up to 468 GPM and pressures up to 125 PSI.

Roper Pumps

The Roper Pumps 3600 series, in particular, comprises general-purpose pumps capable of handling mixing, blending, recirculating, fixed, and mobile transfer tasks, with capacities of up to 468 GPM and pressures up to 125 PSI.

Notably, these pumps come with standard materials of construction, including Cast Iron housings, Cast Iron gears, Bronze bearings, and Steel shafts. Moreover, you have the option to equip them with Bronze, Stainless Steel, or Delrin (Idler only) gears, Iron or Carbon bearings, and Stainless Steel shafts.

These pumps, on the other hand, demonstrate smooth and efficient operation in both rotational directions. Moreover, they excel in managing heavy and viscous materials, such as asphalt, molasses, roofing compounds, and printing inks. Additionally, they are highly effective with fuel oils, various types of gasoline, and similar thin liquids. Furthermore, various materials of construction are available, and the pumps can be provided with or without built-in relief valves.

Additionally, you can assemble them in either a high-drive or low-drive configuration and choose between a conventional packed box or a lapped-face mechanical shaft seal. Moreover, you can directly drive these pumps, or alternatively, drive them through a built-in gear reducer that offers a wide range of ratios. Importantly, their performance stays consistent regardless of the mounting setup or the direction of rotation.

Roper Pumps 3600 Series Features

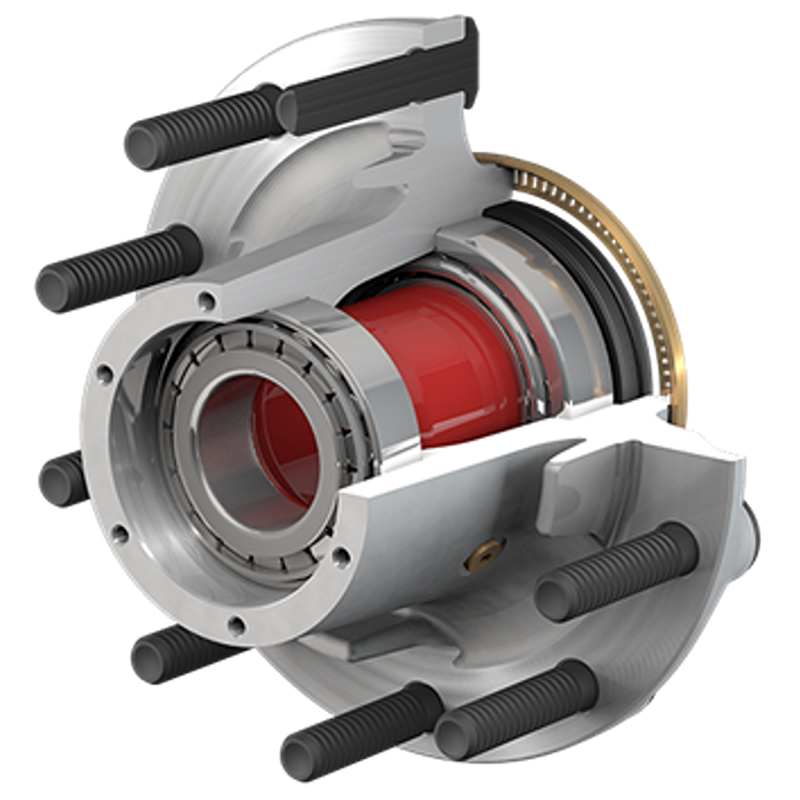

Quiet-Running Helical Gears:

- Heat-treated cast-iron pumping gears, accurately machined for quiet and efficient operation, deliver long-lasting performance.

- Pumping gears are securely keyed to their shafts with a sliding fit and can be easily replaced.

- Precision machining ensures proper meshing, minimizing friction and vibration.

Long-Lasting Bearing Surfaces:

- Special wear-resistant, high-lead bronze bearings, and there is an option for Iron and Carbon bearings as well.

- Four heavy-duty sleeve bearings offer robust support to the pumping gears, ensuring prolonged and efficient service.

- Bearing grooves facilitate the circulation of pumped liquid for lubrication and temperature control.

- An outboard drive shaft bearing supports external radial loads and absorbs axial thrust loads.

Precision-Ground Shafts:

- Harden steel shafts in the bearing and sealing areas and precision ground them to exacting standards to maximize their lifespan.

- Hardened stainless steel shafts are also available.

Rugged Housings:

- Standard castings are made of cast iron.

- Precise manufacturing tolerances result in minimal clearances, maximizing pumping efficiency.

- Large, hardened steel dowel pins guarantee positive alignment between the faceplate, case, and backplate.

| Weight | N/A |

|---|---|

| Shaft | |

| Bushings | |

| Drive | |

| Relief | |

| Seals | |

| Size | 2", 3", 4" |